Plastic-Welding

Pioneer of plastic welding and cutting technology

Plastic and/or textile welding / fusing / jointing / sealing and processing technology utilizes many different methods to achieve a desirable result.

Ultrasonic vibration, high-frequency energy, laser, electromagnetic induction, and vibration are just a few examples of the techniques used in thermoplastic welding and fusing.

Seidensha is a comprehensive manufacturer of welding / melting equipment for nearly all methods and can solve issues related to plastics processing. Based on the vast knowledge accumulated in the long history, we select and provide the ideal method for each customer.

Ultrasonic Welder

Ultrasonic Metal Welder

The ultrasonic welder is used for welding, riveting, cutting, metal joining and sealing with frictional heat generated by ultrasonic vibration. In addition to press type, unit to be integrated into automation system are available.

The ultrasonic metal welder joints aluminum, copper and nickel through solid phase joining technology. Jointing different materials is possible.

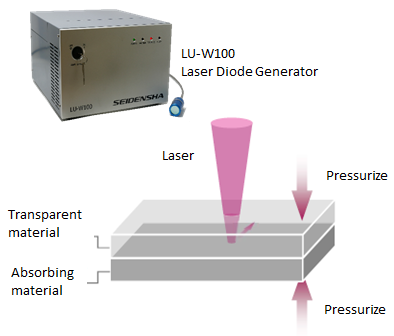

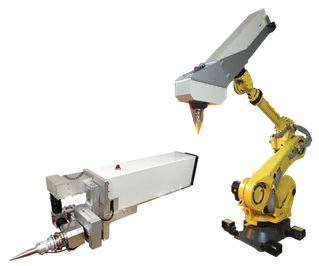

Laser Diode Welding Machine

Laser Diode Generator

Laser diode welding system with built-in air cooled laser oscillator for thermoplastic and textile material.

Laser Diode Generator optimized for Welding Machine. Compact design, air-cooled and high efficiency. Good for building into custom system.

CO2 Laser Machine

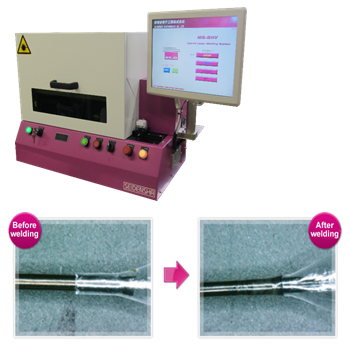

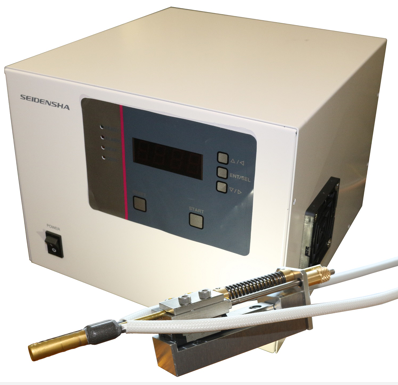

Balloon Catheter Welder

CO2 Laser machine is used for cutting thermoplastic and textile material and scribing ceramic substrates.

Balloon Catheter Welder with Unique Patented technology. Very precise welding is achieved by local heating technique.

Electromagnetic Induction Welder

High-frequency Welder

The electromagnetic induction welder is used for heating metal insert for insertion and/or heating metal plate to be used for heating workpiece to be jointed.

High frequency welder can be used for welding / cutting PVC films, leather and even olefin based materials.

Vibration Welder

Impulse Sealer

Vibration Welder joints thermoplastic parts by frictional heat generated by vibrating one of the workpieces at high speed while pressurizing. Good for larger workpiece even with irregular shape.

Impulse Sealer is used for riveting thermoplastic stud. Stud is heated to melt by heating tip instantly at low voltage / high current. Precise riveting is possible.

OEM Parts components and accessories

OEM parts, horn (sonotrode), components and accessories are available for integration into automation system and retrofit as well as for other brands system.

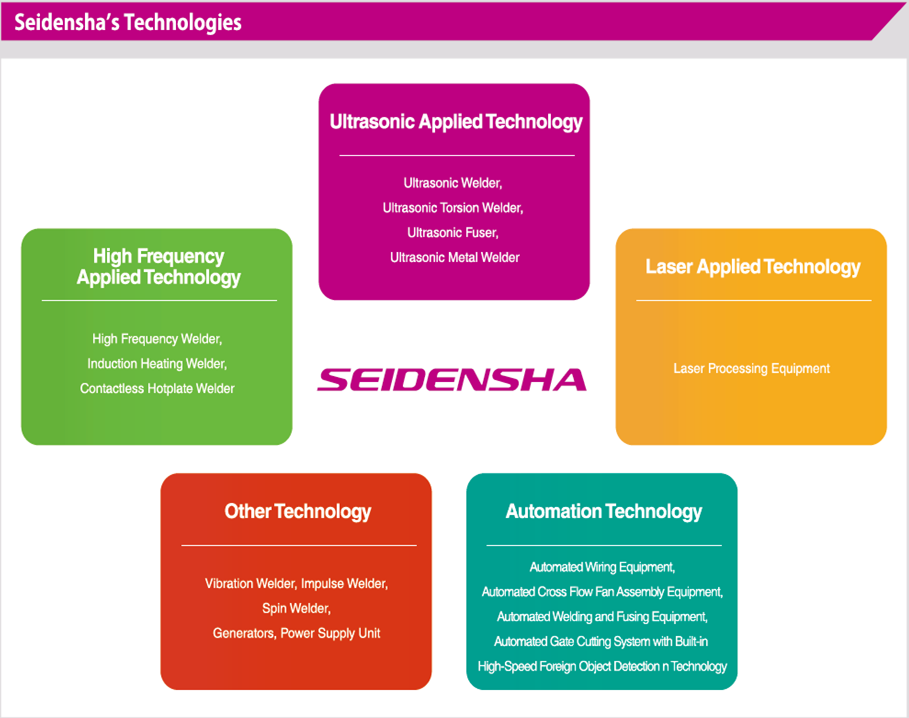

SEIDENSHA is a comprehensive manufacturer of welding, melting, jointing and cutting with various technology background not only in ultrasonic but also laser, high frequency, vibration etc…

Link to Seidensha Electronics Co., Ltd.