Ultrasonic Motor

Piezo Sonic Ultrasonic Motor ( Piezoelectric Motor ) with no magnets and no coil has lightweight, compact, high torque, silent and accurate control features.

Good for strong magnetic field application, such as MRI.

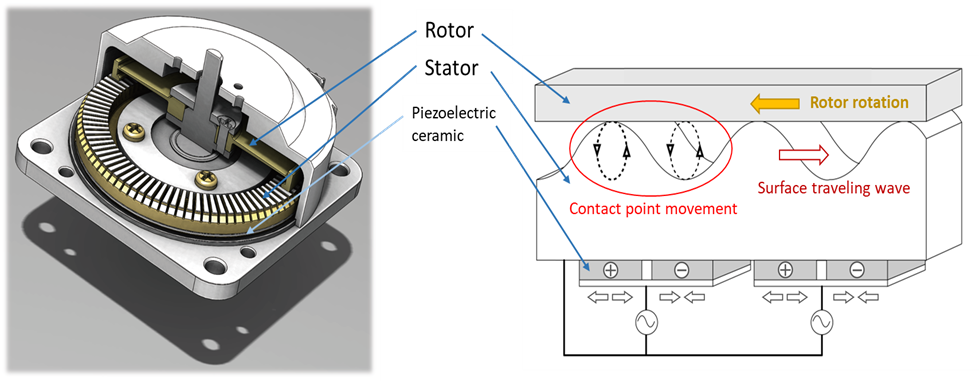

What is Piezo Sonic Ultrasonic Motor?

Movement of Piezo Sonic Motor is made by physical deformation of the piezoelectric ceramic, which is amplified and transferred thru. the stator and, then, this stator wave vibration rotates the rotor by friction force.

Since frequencies of sound waves generated by PiezoSonic Motor is higher than the audible limit, it is also called Ultrasonic Motor.

Features of Piezo Sonic Ultrasonic Motor

- Use no magnets or coils for movement.

- Completely non-magnetic motor (Series N) available. Good for Semiconductor production or MRI magnetic field application. (MRI compatible)

- High torque at low speed

- Highest torque to hold position at zero power

- No backlash

- No reduction gear required

- Accurate position control by direct drive

- Compact, light weight

- Silent movement

- Long life compared to conventional ultrasonic motor

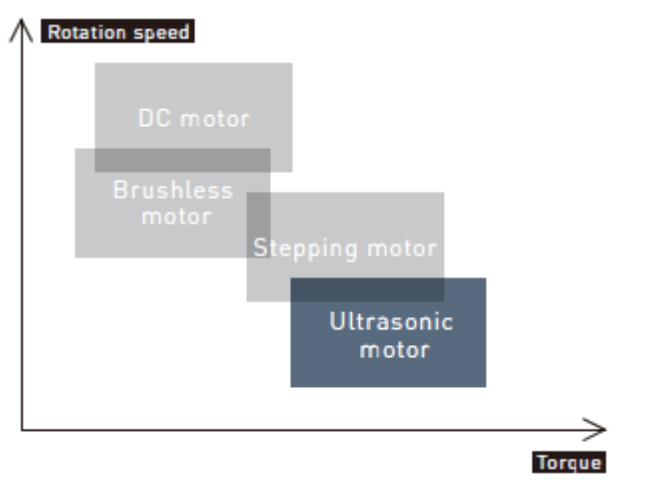

Piezo Sonic Ultrasonic Motor vs Other type of Motors

Rotation speed vs Torque

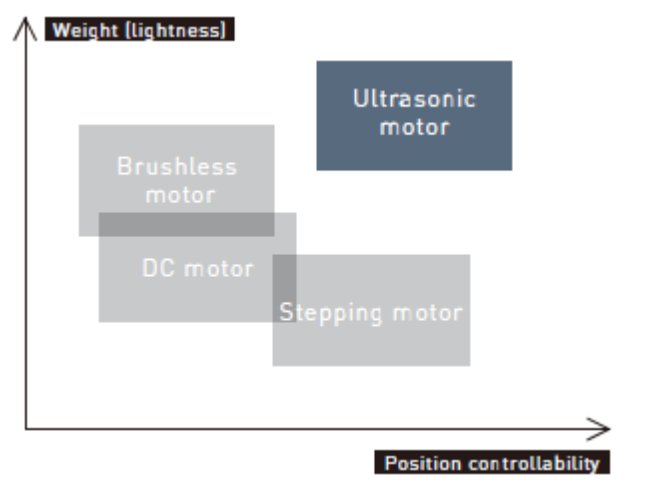

Weight vs Position controllability

Piezo Sonic Motor has high torque at low speed feature because of friction force between rotor and stator.

Direct Drive actuator system without any gear is possible.

Piezo Sonic Motor is lightweight with small inertia and capable to stop quickly by friction force.

Application

– Medical MRI environment with strong magnetic field (*)

- Actuation / Positioning

- Contrast Media Injector

- Dosing Pump

- Positioning / Actuation

- Air circulation / FAN

– Robot arm actuator

– Strong radiation environment

– Limited space application

– Gimbal device

– Space environment

* Electromagnetic interference ( EMI ) between magnetic resonance imager ( MRI ) and manipulator is a severe problem as EMI degrades the image quality. Piezo Sonic’s completely non-magnetic motor (Series N) is ideal for such application.